The Anycubic Kobra Max solves a lot of pain points with its fast assembly, auto bed leveling system, and easy-release coated glass bed. It is a monster of a machine and still reasonably priced at $569

Pros

- +Massive build size

- +Accurate auto bed leveling

- +Build plate releases when cool

Cons

- –Massive footprint

- –Bed Slinger

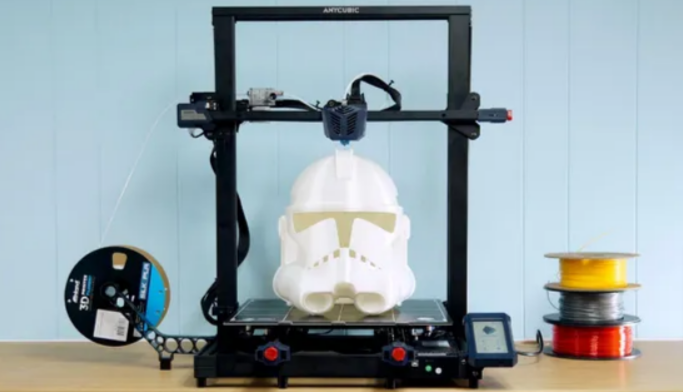

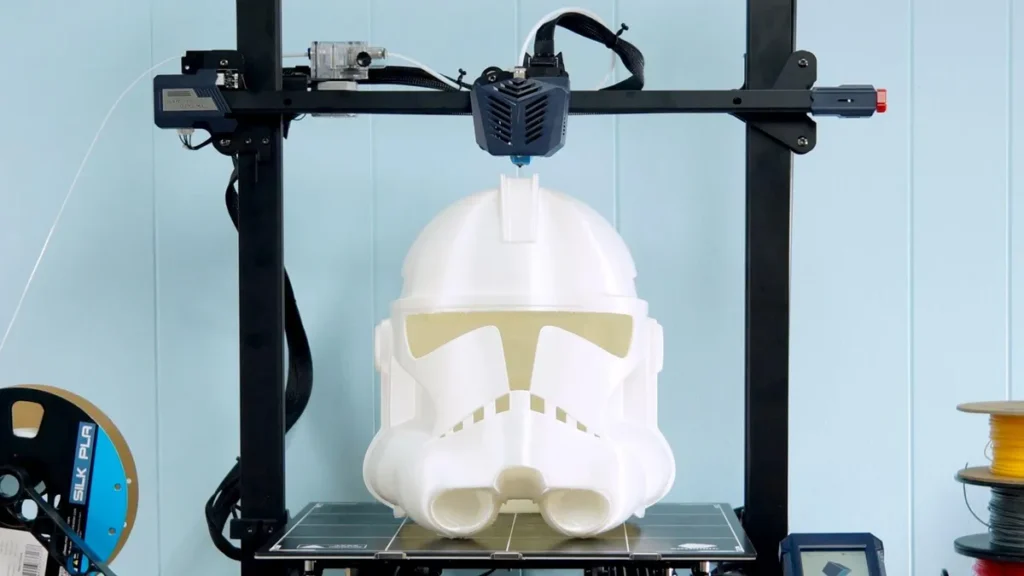

The Anycubic Kobra Max is freaking huge. No really. It’s that big. With a 400x400x450mm build volume, this is the perfect machine for 3D printing props and costume helmets in one piece.

But first, you’ll want to measure your workspace – this monster needs THREE SQUARE FEET of operating space! I had to turn the printer sideways to fit on my IKEA counter – and the spool holder still hung off into space.

Once you find a spot to put it, the Anycubic Kobra Max is a great machine that’s easy to use. Available starting at $569, the Kobra Max is a Bowden-type printer with a Volcano-style hot end and a coated glass bed. It has an auto-leveling system that physically taps the glass surface, giving very accurate results that can hang with any of the 3D printers.

If the thought of prying giant prints off a glass bed sounds terrifying, worry not. Anycubic’s carborundum glass formula is perfect – just let the glass cool down and it will release on its own. I’ve only had to nudge a few small pieces off the bed with a spatula. Large prints have always slid off without a fight.

Despite the size, the Kobra Max is almost as easy to assemble as its little brother, the Anycubic Kobra. It ships mostly assembled in two large sections and only needs a handful of screws and bolts to assemble.

Four bolts hold the gantry in place, then a brace is attached from the top of the machine to the back. A few more screws attach the touch screen, while the spool holder snaps onto the base.

Next, clip off the zip ties that held the printer together for shipping and plug in the wiring. Everything is clearly labeled. The final step is to secure the Bowden tube to the print head cable with the provided cable clips and zip tie the cable to the support rod if you wish.

After the printer is assembled, you should check for loose or over tight parts – make sure all the wheels are snug but roll smoothly, the print carriage doesn’t have any wiggle and the belts are tight.

The Kobra Max has eccentric nuts you can tighten with the provided wrench, plus easy-to-use belt tension knobs for the X and Y axis.

Please note, the Kobra Max has two Y axis belts. You’ll want to make sure each belt has about the same amount of tension for smooth printing. It takes about 30 minutes to carefully assemble.

The Anycubic Kobra Max looks like a giant hybrid of the Anycubic Kobra and the older Anycubic Vyper. It has the Vyper’s angular print head cover and the Kobra’s smaller tension knobs, which combined with the smooth metal frame gives it a polished look.

It uses an open frame design at the base to avoid extra weight, which is good because it already weighs 35 pounds. The power supply and processor tuck under the build surface and the machine can be picked up in one piece.

I should note that the spool holder snaps on to the side, which makes the entire printer about 3 feet wide. I had trouble fitting it through doors, so it’s best to build it in the room where you plan to use it.

The printer may be a “bed slinger” but it’s built for stability. It has dual Z rods synced up with a belt, two widely spaced Y axis and braces that hold the gantry steady.

It has silent stepper motors, but you will hear the fans. Still, Anycubic says the operating noise is under 60dB, so it’s quiet compared to many machines.

- The build plate is a carborundum coated glass, held on with six clips. Most prints simply release when the bed cools down. The bed can reach temperatures of 90 C.

- The hotend is a Volcano style that can reach 260 C, hot enough for most consumer grade materials. Despite being a Bowden machine, I had excellent results with TPU.

The touch screen is the same 4.3-inch display as on the Anycubic Kobra. The menu is easy to navigate for beginners, with options in logical locations. The home screen has four options: Print, Prepare, Tools and System.

- Print shows you a list of files on the microSD card you can choose.

- Prepare has menus for Leveling, Preheat and Filament loading.

- Tools has Move Axis, Temperature, Speed and Motor. Motor is where you disable the steppers if you need too.

- System lets you pick the language (English or Chinese), Voice (turn off the beeps) and About.

Preparing Files / Software

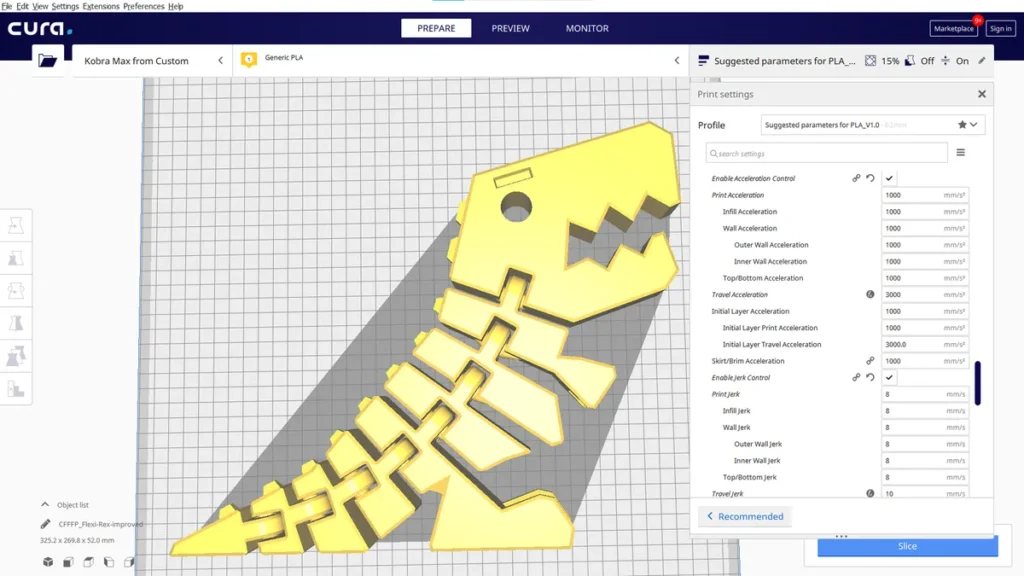

The Anycubic Kobra Max comes with Cura 4.2.1 and a profile for PLA and TPU. These profiles do not work with newer versions of Cura, so it’s worth downloading version 4.2.1 just to check out the profile settings.

Directions are included in the manual for making a custom printer to match the Kobra Max settings. The “PLA profile” has important tweaks to slow down the default Ultimaker acceleration and jerk settings, which are too much for a massive machine like the Max. Acceleration is slowed to 1000 mms and Jerk is reduced to 8 mms.

To load the profile, click Preferences → Configure Cura → Profiles then select Import from the tabs.

If you’re wanting to use a newer version of Cura you can load a printer profile for a Creality Cr10, then adjust the build volume to 402 x 402 x 452. This setup already has the acceleration and jerk slowed and is what I used during testing.

If you’re looking to save time, print at .28mm layer height, and increase your line width to .64mm. This is the same effect as swapping to a .6mm nozzle without the work.

It will increase the amount of filament used, but make a drastic impact on time without hurting quality. This Flexi Rex takes 50 hours printed at .28mm layer height at a default .4 line width. I saved 13 hours by increasing the line width to .64mm.

Verdict:

The Anycubic Kobra Max is a monster of a machine and still reasonably priced at $569. It’s perfect for prop makers and cosplayers who could fit whole helmets and armor pieces inside the generous 400x400x450 mm build volume. It’s also useful for makers who want to load many small objects that can print at the same time.

The Kobra Max solves a lot of pain points with its fast assembly, auto bed leveling system and easy-release coated glass bed. Though the printer is aimed at experienced makers yearning for greater build space, there’s no reason a novice wouldn’t excel with this machine.

Buyers should be aware that the Kobra Max is a bigger 3D printer, not a faster 3D printer. Large prints will take more time – days even – and rushing this printer could hurt quality.